The use of hot melt adhesive

Hot melt adhesive is a new type of solvent-free environmentally friendly material. The formula is designed with polyurethane as the basic structure. It is solid at room temperature. When heated above the melting point, it will melt into a viscous liquid. It is reversible thermoplastic material, which has good elasticity, softness and low temperature tortuosity resistance, and has a strong bonding effect on a variety of different materials.

Advantages of hot melt adhesive

Because it is solvent-free and 100% solids, there is no flammability or explosion hazard during processing and shipping. In addition, there are the following advantages:

(1) The solidification speed is fast, and the cooling is solidified, the production speed is high, and the equipment space is saved.

(2) The bonding process is simple, the waste is less, and there is no problem of mixing ingredients.

(3), 100% solidified components, can be fully utilized, less waste, can reduce transportation and storage costs.

(4) A wide range of substrates that can be attached can be processed automatically.

(5), excellent chemical and physical properties, with high adhesive strength and flexibility.

(6), no organic solvent is used, no VOC pollution problem.

(7), environmentally friendly materials, waste can be naturally degraded.

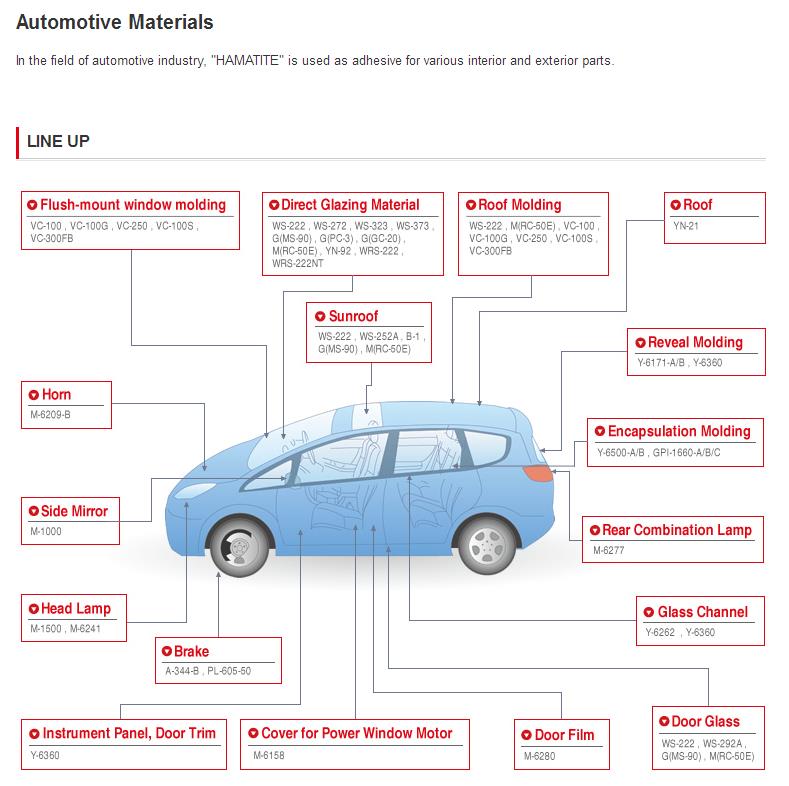

Application of hot melt adhesive in automobile

For example: headlights/seats/dashboard ventilation ducts/accelerator pedals for cars/lost foam for car engine intake pipes, etc...

How to use hot melt adhesive

Generally, the people who use the hot melt gluer are more experienced professionals, but sometimes there are

non-professionals who need to operate, whether professional or non-professional, pay attention when operating the hot melt gluer Safe and cautious.

Generally, operators who use hot melt adhesive operate according to the on-site instructions and instructions of the equipment manufacturer, but in fact, the operation of hot melt adhesive is still very particular. Now we

Shanghai Lichi Industrial Co., Ltd. recommends customers to operate as follows:

1. The temperature should be moderate (150-160 ℃), and cannot be heated above 200 ℃ for a long time, which

will cause damage to the glue, promote the premature aging of the hot melt adhesive, and affect the bonding effect. Before construction, heat for 40 minutes to 60 minutes. Wait for the hot melt adhesive to melt into a liquid before applying.

2. After feeding into the hot melt glue tank, the cover of the glue tank should be closed immediately to avoid contamination by foreign impurities; if the temperature is appropriately lowered to 120 ℃ during the rest period, the temperature can be kept in a heat preservation state.

3. When leaving get off work every day, in addition to turning off the power of the machine, it is also necessary to put the remaining glue in the melt tank on the release paper, which can be used the next day; if the remaining glue is not released, the cover of the melt tank must be opened. , to speed up the heat dissipation, and put two pieces of cold glue into the glue tank to promote cooling.

4. When the machine is used for a period of time (for example, 3 months), the nozzle, hose and glue tank should be cleaned regularly with "Banglin" special cleaner to avoid impurities or carbon deposits affecting the construction of the machine. Refer to before use. Product technical specification.

The quality assurance of hot melt adhesive is very important, but the correct construction operation of hot melt adhesive has a more guarantee for the quality of hot melt adhesive.